Introduction to Polyimide PCBs

Amid the waves of lightweighting, thinning, flexibility and high reliability in the electronics PCB industry, LHDT TECH has always been at the forefront of innovation, leading the evolution of printed circuit boards (PCBs) technology. With our in-depth mastery and advanced application of polyimide materials, we have transformed their outstanding physical and chemical properties into the core advantages of high-performance and flexible printed circuit board design.

By integrating polyimide material technology into our product design and manufacturing processes, LHDT TECH not only pushes the boundaries of circuit miniaturization but also empowers a series of cutting-edge fields: from the lightweight fit of wearable devices to the precision and reliability of medical instruments; From the durability and adaptability of automotive electronics to the harsh challenges of extreme environments in aerospace. Based on materials science, we continuously provide thinner, more flexible and more robust circuit solutions for customers in various industries, contributing to the birth of the next generation of electronic products. polyimide circuit boards offer unique material properties that make them the preferred type of material for next-generation circuit board fabrication. At LHDT TECH, polyimide is not merely a material; it is the key carrier for us to achieve technological breakthroughs and create future electronic forms.

For many designers, polyimide becomes the material of choice not just for its proven track record but because the combination of thermal resistance, electrical insulation properties, flexibility, and strength simply can’t be matched by conventional PCB materials like FR-4. This article dives deep into the world of polyimide PCB material, exploring what makes polyimide ideal for flexible printed circuit boards and how these advanced PCBs are manufactured for the most demanding electronics applications.

What is Polyimide? Polyimide Material Explained

Polyimide, as a type of high-performance synthetic polymer containing imide monomers, is renowned for its outstanding high-temperature resistance, excellent mechanical stability and remarkable dielectric properties.We delve deeply into its potential at the molecular level. Through precise synthesis and process control, we transform its inherent properties such as resistance to extreme temperatures, anti-deformation, and insulation stability into the guarantee for the circuit’s long-term and reliable operation under complex working conditions. It is precisely because of its profound understanding and advanced application of such top-notch engineering polymers that LHDT TECH has successfully extended polyimide from applications that meet extreme environments to broader commercial and industrial high-end circuit fields, defining a new material for flex and high-performance circuits.

Key Polyimide Material Properties

- High Temperature Resistance: The high-temperature resistance of polyimide stems from its unique aromatic heterocyclic molecular structure, which provides thermal stability far exceeding that of conventional PCB substrates. Its continuous operating temperature can consistently exceed 260°C, and certain high-performance series can even withstand extreme thermal shocks of over 400°C for an instant. This characteristic makes polyimide circuit boards an inevitable choice for addressing severe thermal management challenges.

- Stable Electrical Properties: The stable and predictable low dielectric constant (Dk, typical value ~3.2-3.5) and extremely low loss tangent (Df) of polyimide have laid an irreplaceable materials science foundation for its application in high-speed and high-frequency circuit design. This core electrical characteristic directly determines the fidelity and efficiency of signal transmission.

- Excellent Flexibility: The outstanding mechanical properties of polyimide substrates stem from the unique toughness, high tensile strength and excellent fatigue resistance of their polymer chain structure. The nature of this material makes it an ideal carrier for realizing reliable dynamic flexible circuits.

- Chemical Inertness: The outstanding chemical inertness of polyimide stems from its highly stable aromatic molecular structure, which endows it with intrinsic resistance to a wide range of chemical erosions. This characteristic surpasses that of ordinary pcb material, providing a fundamental guarantee for the long-term reliable operation of electronic devices in harsh or sensitive chemical environments. Make it an inevitable choice in the fields of automobiles, industrial control and experimental instruments.

- Radiation and Flame Resistance: Polyimide materials, with their inherent flame-retardant and radiation-resistant properties, have become an ideal choice for dealing with extreme environments. This feature is the core guarantee for circuit boards in spacecraft, satellites and highly reliable military electronic equipment. Our solution can effectively resist the risks of space radiation and high temperatures, providing an intrinsically safe and reliable foundation at the material level for critical mission systems.

- Low Outgassing: With its extremely low gas release, polyimide is an inevitable choice for circuit applications in satellite vacuum environments and high-precision laboratory instruments, eliminating the pollution risk caused by material volatilization from the root.

These material properties make polyimide not just an alternative, but a superior PCB substrate for many modern electronics and the material used wherever failure is not an option.

Key Properties of Polyimide PCBs

What really sets polyimide PCBs apart from standard FR-4 PCBs or other substrates?

Core Advantages of Polyimide PCB Material

Polyimide, with its comprehensive performance, has become a cornerstone material for high-end electronic applications. Its core advantages are reflected in: Superior Flexibility, supporting high-density deformation assembly and folding design; High Tensile Strength ensures vibration and shock resistance for high dynamic applications. Wide-range thermal stability, maintaining dimensional and electrical stability at temperatures above 260°C on the thermal Stability. Outstanding high-frequency performance and extremely low and stable Dk/Df values ensure signal integrity. It has superior Chemical and Radiation Resistance and Stable Electrical Insulation Properties, making it suitable for extreme environments such as space and chemical industries. These characteristics together constitute its irreplaceable position in fields such as aerospace, high-frequency communication, wearable devices and advanced automotive electronics.

Properties that make polyimide the base polyimide of choice:

- Its heat resistance far exceeds that of FR-4:Maintain structural integrity and electrical performance stability at high temperatures.

- Achieve an extremely thin and light design:It can replace heavy hard boards, significantly reducing weight and volume.

- Ensure long-term reliability for strict applications:Ensure consistent performance in the most challenging environments.

Types and Grades of Polyimide for Printed Circuits

Not all polyimide PCBs are the same. In the PCB industry, the type of polyimide chosen greatly influences a board’s cost, flexibility, and overall reliability.

Popular Polyimide Grades

| Polyimide Grade | Key Feature | Common Use | Example Application |

| Kapton | High temp/flexibility | Space, Medical | Flexible printed, satellites |

| Apical | 400°C endurance | Aerospace | Avionics flex circuits |

| UPILEX | Mechanical strength | Industrial | Robotics circuit boards |

| Durimide | Fine-feature imaging | HDI/Multilayer | Advanced PCB fabrication |

Filled Polyimide: Offers strength for rigid-flex and multilayer applications.

Low-Flow Polyimide: Modified for layered stackups needing low resin flow during lamination.

Manufacturing Process for Polyimide Circuit Boards

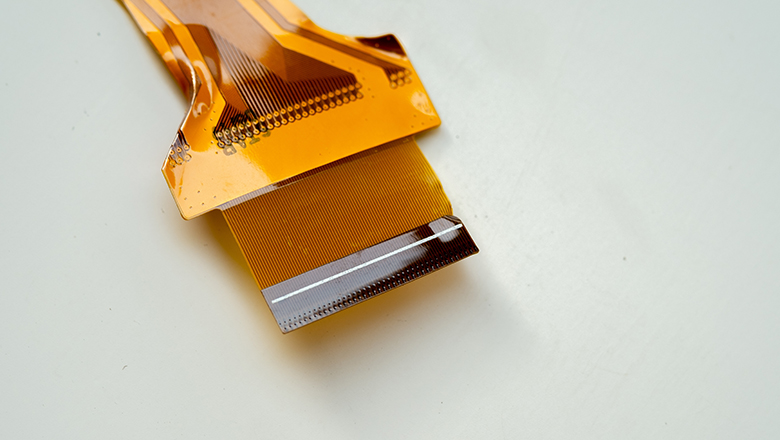

Polyimide PCB manufacturing is an advanced process. The manufacturing process for polyimide starts with creating thin polyimide films or sheets (the base material), which are then laminated with copper using controlled heat and pressure.

Step-by-Step Polyimide PCB Manufacturing Process

- Substrate PreparationPolyimide resin is cast into thin flexible films, cut to size, and cleaned. Surface treatments improve copper adhesion.

- Copper LaminationCopper foil is laminated to the polyimide substrate, forming the circuit board material

- Photolithography & PatterningPhotoresist is applied and exposed to UV, defining circuit traces for printed circuits. Unwanted copper is etched away.

- Multilayer Stacking (if required)For multilayer polyimide flexible PCBs, additional copper and polyimide layers are laminated using adhesives that match the board’s flexibility and thermal expansion.

- Drilling and PlatingVias and holes are drilled and plated with copper for through-hole connections.

- Protective FinishingCoverlay or solder mask is applied; gold or tin may be plated on pads.

- Testing and InspectionBoards are electrically tested and visually inspected for circuit continuity and manufacturing defects. Especially in high-reliability PCB assembly, thermal cycling and bend tests are routine.

Configurations: Single, Double, and Multilayer Polyimide Flexible PCBs

The diversity of polyimide PCB materials enables it to cover all designs from simple single-layer to complex multi-layer flexible printed circuit boards (FPCBs), precisely meeting the diverse professional demands in the electronics industry.

Single-Sided Polyimide Flexible PCBs

- Material Used:One layer of copper bonded to a polyimide substrate.

- Typical Use:Used in flexible interconnects, dynamic cabling, small IoT devices, and medical sensors. These are the most economical choice for simple circuit routing requiring flex but minimal layer complexity.

- Advantages of Polyimide:Maximum flexibility, light weight, and low manufacturing cost for simple flex PCBs.

Double-Sided Polyimide Flexible PCBs

- Material for Flex:Two copper layers sandwiching the polyimide insulation layer, linked by vias or through-holes.

- Typical Applications:Wearable technology, medical diagnostic sensors, digital displays, and automotive control circuits where higher component density is necessary.

- Why Polyimide is Preferred:The additional copper layer supports more sophisticated circuit design and greater functional complexity without sacrificing flexibility or the inherent advantages of polyimide.

Multilayer Polyimide Flexible PCBs

- Base Polyimide:Three or more polyimide/copper layers create advanced FPCBs, often combining both flexible and rigid regions.

- Applications:Used in aerospace, advanced driver assistance systems (ADAS), folding phones, satellites, and military communication gear, requiring the absolute highest circuit density, EMI control, and reliability.

- Stackup Flexibility:Enables controlled impedance, power/ground planes, shielding, and flexible-rigid transitions—all using stable electrical properties unique to polyimide.

Polyimide PCB vs. FR4 PCB: Materials and Performance Comparison

In the crucial decision-making process ofPCB material selection, the performance comparison between polyimide vs FR4 usually directly determines the technical height and application boundary of the PCB industry solution.

What is FR-4 Material?

FR-4 is a composite material made of glass fiber reinforced epoxy resin, and the “4” in its name directly corresponds to its UL94V-0 flame retardant standard. As the most widely used standard substrate for rigid circuit boards, it is ubiquitous in various electronic products ranging from personal computers to industrial control systems.

Polyimide vs FR4: PCB Comparison Table

| Feature / Parameter | Polyimide PCBs | FR-4 PCBs |

| Temperature Resistance | Up to 400°C | ~130°C (max ~140°C) |

| Flexibility | Superior, used in flexible | Rigid |

| Dielectric Strength | High, stable over temp | High, less stable above 120°C |

| Chemical Resistance | Excellent | Good |

| Moisture Absorption | Low | Moderate |

| Material for Flex | Yes | No |

| Miniaturization Support | Exceptional, thinner possible | Limited by board thickness |

| Cost | Higher (premium price) | Lower |

| Signal Integrity | Stable at high frequencies | Good for moderate speeds |

| Applications | Medical, aerospace, wearable | Computers, industrial |

Advantages of Polyimide Over FR-4:

- Polyimide PCBs offer superior performance for demanding pcb applications that require higher temperature tolerance, flexibility, or exposure to harsh chemicals.

- Polyimide is the basic material for dynamic flexible printed circuits, while FR-4 offers a more economical and reliable solution in static rigid designs.

When to Prefer Polyimide:

- Miniaturized circuits, circuits exposed to vibration, flex assemblies, or those operating at extreme temperatures.

- Rigid circuit regions combined with flex regions (rigid-flex).

- Applications in which stable electrical properties and mechanical reliability are a must.

Typical Performance and Design Specifications

Polyimide circuit boards can be customized according to strict performance requirements. The type of material performance specifications are as follows:

| Spec / Property | Polyimide Flexible PCBs | Typical Value | Remarks / |

| Substrate Thickness | 12-150 μm | Customizable | Enables ultra-thin flex PCBs |

| Copper Foil Thickness | 9-70+ μm | Depends on design | Lower for flex, higher for power |

| Dielectric Strength | ≥160 kV/mm | High | Essential for high voltage circuits |

| Glass Transition (Tg) | 300–400°C | Superior to FR4 | Determines temp stability |

| Thermal Expansion Coeff. | 10-30 ppm/°C | Low/Stable | Dimensional stability crucial |

| Moisture Absorption | <0.5% | Low | Resists environmental effects |

| Outgassing (NASA ASTM E595) | <1.0% TML, <0.1% CVCM | Ideal | Space & medical applications |

| Circuit Traces Minimum | Down to 25 μm (1 mil) | HDI Supported | For high-density layouts |

| Maximum Service Temp | 260–400+ °C (by grade) | Premium | For reflow & harsh environments |

Pros and Cons of Polyimide Flexible Printed Circuit Boards

Advantages of Polyimide:

- Outstanding thermal stability and mechanical properties: It remains stable at high temperatures, enabling circuit miniaturization and dynamic bending, providing reliable protection for circuits in continuous bending or extreme stress environments.

- Excellent environmental resistance and electrical insulation: With outstanding chemical resistance and high dielectric strength, it ensures stable operation of the circuit in harsh or mission-critical applications.

Potential Disadvantages:

- Polyimide comes at a premium price. The PCB manufacturing process for polyimide flexible PCBs is more complex, requiring experience in the PCB industry.

- Circuit board manufacturing lead times can be longer due to specialized processes. Not all PCB houses can fabricate polyimide as the flexible insulating material or deliver tight specs for HDI or medical applications.

- Some applications may not require the superior performance polyimide PCBs offer—FR4 stands as the economical standard for everyday rigid circuit boards.

Trends, Innovations, and the Future of Polyimide PCBs

The demand for reliable, flexible, and ultra-small printed circuits continues to drive the adoption of polyimide in the pcb industry:

- Hybrid and 3D Circuits:Combining polyimide with ceramic or glass substrates for even better heat spreading and integration with component base materials.

- Eco-friendly, Halogen-free Polyimide:Safer disposability for wearables, medical waste, and consumer electronics.

- Mobile & IoT:Polyimide makes truly “wearable” electronics practical, powering flexible batteries, smart clothing, and miniaturized sensor nodes.

- AI and Edge Computing:Circuits “hidden” in curved or dynamic surfaces, enabled entirely by the properties of polyimide flex PCBs.

Frequently Asked Questions: Polyimide Circuit Boards

Q: Why use polyimide instead of fr4 pcb in flexible printed circuit boards?

A: Polyimide outperforms FR-4 in terms of high-temperature resistance, flexibility and electrical performance stability, making it an ideal material for coping with harsh environments such as dynamic bending, extreme temperatures or chemical corrosion. The FR-4, with its economy, has become a reliable choice in rigid circuit designs that do not require bending. The two respectively define the material standards in high-performance and cost-optimization scenarios.

Q: Are there different types of polyimide for PCB substrates?

A: Yes, the polyimide material system includes various types to meet different design requirements: pure polyimide offers the highest level of flexibility and thermal stability; The third-generation product has added flame retardants. The filling type enhances mechanical strength through reinforcing materials. Low-flowability polyimide, on the other hand, optimizes the size control in the lamination process. These types each have their own focuses in terms of flexibility, rigidity and temperature resistance, enabling engineers to precisely match the specific requirements of flexible, rigid or rigid-flex combined applications.

Q: Can polyimide circuit boards be used in high-frequency circuits?

A: Completely correct. Polyimide, with its stable low dielectric constant and extremely low loss factor, has become an ideal material for high-frequency and microwave circuit design. In fields such as radio frequency and 5G where signal integrity is highly demanded, it is often given priority as a key flexible insulating medium.

Q: What are the challenges with circuit board fabrication using polyimide?

A:The core challenge in the manufacturing of polyimide flexible circuits lies in its special process control: it is necessary to maintain the geometric accuracy of the circuit during dynamic bending, ensure the interfacial bonding force between the copper layer and the substrate to avoid delamination, and meet the strict standards for gas release rate in fields such as aerospace and medical. Therefore, cooperating with manufacturers with profound process experience (such as LHDT TECH) is the key to achieving high-reliability circuit manufacturing.

Q: How thin can a polyimide circuit board be made, and how does this compare to FR4?

A:Polyimide flexible circuits can achieve an ultimate thickness of 25 microns (1 mil), meeting the ultra-thin design requirements of medical sensors, wearable devices, etc. However, due to its rigidity, the thickness of FR-4 material is usually difficult to be less than 0.2 millimeters.

Q: What circuit board materials are typically used for wearable or flexible PCBs?

A:Polyimide, as the most widely used material in the field of flexible circuits, is also the core substrate for high-density interconnection, dynamic bending and integrated sensing circuits. Compared with other special flexible materials, it achieves the optimal comprehensive balance among flexibility, electrical insulation and heat resistance.

Conclusion: Is Polyimide PCB Right for You?

Polyimide circuit boards have become an essential technology across the electronics landscape. Polyimide pcbs offer superior performance in flexibility, high temperature operation, stable electrical properties, and chemical endurance—traits that are increasingly required in advanced PCB applications.

- For wearables, IoT, medical sensors, automotive electronics, aerospace, and anywhere circuits must endure mechanical flexing, heat, or harsh environments, polyimide flexible PCBs are the only proven solution.

- While polyimide comes at a premium price compared to fr4 pcb, the increased reliability, longer lifecycle, reduced weight, and ability to meet design requirements for today’s most innovative electronics often justify the investment.

LHDT TECH is well aware that the realization of every cutting-edge innovation, from foldable smartphones and micro medical implants to high-density rigid-flex circuits, is inseparable from the outstanding performance of polyimide materials. Our core value in this field lies in transforming the possibilities of materials into the reality of products. Our accumulated profound experience in PCB manufacturing directly determines the manufacturability, final quality and long-term market success of each design.