Introduction to Ceramic PCB Technology

Printed Circuit Board (PCB) technology has achieved remarkable evolutionary advancements. This progress enables electronic devices to attain ultra-high reliability. These devices can meet high-frequency operating requirements and possess excellent heat resistance. Ceramic PCBs are a significant innovative achievement in this development process. This product is also referred to as ceramic printed circuit boards or ceramic circuit boards.

Ceramic PCBs hold significant value due to their multiple excellent characteristics. It demonstrates outstanding thermal conductivity while providing superior electrical insulation. Its mechanical structure also exhibits good resilience. Currently, various industries generally seek to achieve higher power density in electronic devices, require further reduction in device size, and continuously improve overall performance. The unique thermal and electrical properties of ceramic materials make circuit boards based on this material a key component in meeting these demands. The applications of ceramic PCBs have now expanded to several important fields, including power module equipment, RF amplifier systems, and advanced LED electronic devices, among others.

What is a Ceramic PCB?

A ceramic PCB is a specialized type of circuit board that uses a ceramic substrate as its core material. Its substrate materials include advanced ceramics such as aluminum oxide, aluminum nitride or silicon carbide. Standard FR4 circuit boards are primarily composed of fiberglass and epoxy laminate. The ceramic materials impart excellent thermal conductivity to these circuit boards. Additionally, the ceramic materials offer highly stable chemical properties.

How Do Ceramic PCBs Work?

- Conductive copper(or silver, gold) layers are directly bonded or deposited onto the ceramic substrate.

- Multiple layers of the PCB can be stacked (multilayer ceramic PCBs) to support dense and complex circuit configurations.

- The base ceramic ensures both excellent thermal conductivity and outstanding electrical insulation—making ceramic PCBs suitable for high-frequency and power-intensive roles.

Ceramic PCB vs FR4 PCB

| Feature | Ceramic PCB | FR4 PCB |

| Base Material | Ceramic substrate (Al2O3, AlN) | Fiberglass/Epoxy |

| Thermal Conductivity | High (20–200 W/mK) | Low (0.3–0.5 W/mK) |

| Operating Temperature | Up to 1000°C | Up to 130°C |

| Electrical Insulation | Excellent (10-20kV/mm) | Good |

| Cost | Higher | Lower |

| PCB Applications | High-power, RF, LEDs, automotive | General electronics |

Ceramic Substrate Materials: The Base of Ceramic PCBs

The ceramic substrate forms the core component of all ceramic circuits. The selected ceramic material determines the thermal expansion coefficient of the board while also influencing its thermal conductivity and electrical performance.

Common Ceramic Substrate Materials

- Aluminum Oxide (Al2O3):

- Most widely used ceramic PCB substrate

- Good thermal conductivity(15–35 W/mK)

- Excellent electrical insulation and cost-effective

- Aluminum Nitride (AlN):

- Higher thermal conductivity (120–180 W/mK)

- CTE matches silicon chips, ideal for power electronics

- Preferred in high temperature applications

- Silicon Carbide (SiC) & Silicon Nitride:

- Great for high-frequency and harsh environments

- Superior mechanical and thermal shock resistance

- Beryllium Oxide (BeO):

- Extremely high thermal conductivity (170–260 W/mK)

- Less common due to handling toxicity

- Hybrid Ceramics:

- Custom blends offering tailored thermal and electrical properties

Types of Ceramic PCBs

A variety of PCB types exist in ceramic technology, depending both on the ceramic material and the manufacturing process.

By Material

- Alumina Ceramic PCB(Al2O3)

- Aluminum Nitride PCB

- Silicon Carbide PCB

- Beryllium Oxide PCB

- Hybrid/Composite Ceramic PCB

By Manufacturing Process

| Type of Ceramic PCB | Description | Best Use |

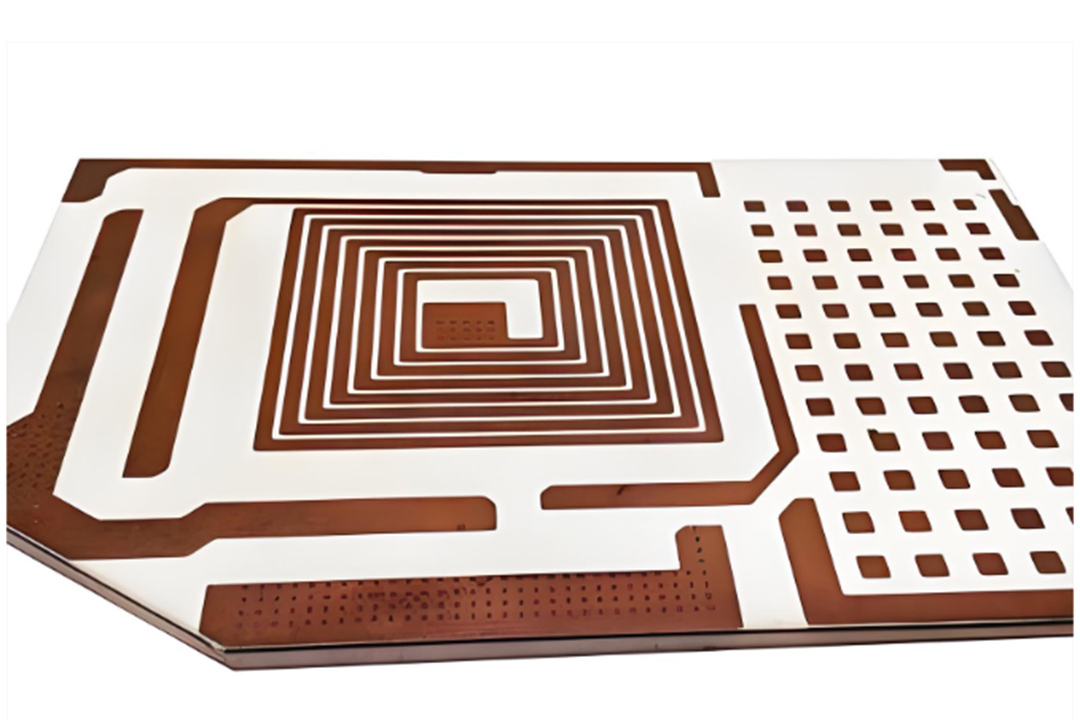

| Thick Film Ceramic | Conductive pastes printed and fired on ceramic | Power hybrids, analog/RF |

| Thin Film Ceramic | Metal layers deposited in thin, precise films | High-frequency, precision |

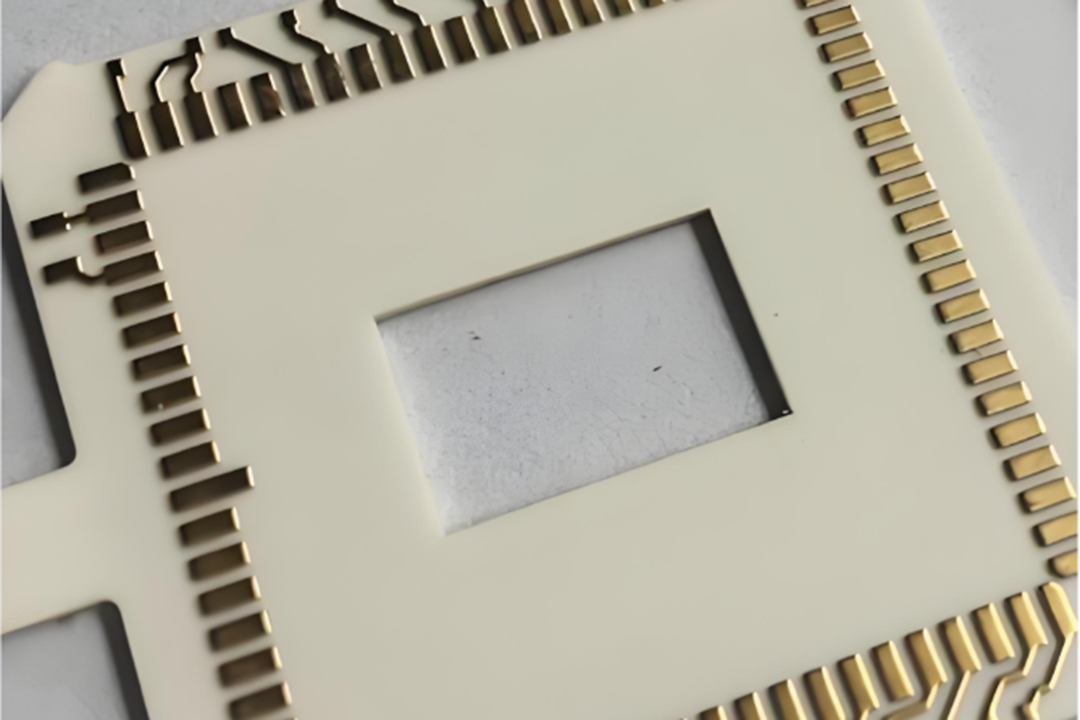

| Direct Copper-Clad Ceramic | Copper bonded onto the ceramic substrate | High-power, LED drivers |

| Low-Temperature Co-Fired Ceramic (LTCC) | Layers co-fired at low temp for 3D routing & passives | Multilayer RF, automotive |

| High-Temperature Co-Fired Ceramic (HTCC) | Layers co-fired at >1600°C for superior durability | Aerospace, military, satellites |

| Multilayer Ceramic PCB | Multiple ceramic layers for dense circuits | Advanced electronics, medical |

Why Use LHD TECH’S Ceramic Board?

- To get higher thermal conductivity compared to FR4 or MCPCB

- For excellent thermal management capabilities in dense, powerful devices

- Ideal where thermal expansion coefficient matching to silicon components is vital

LHD TECH’S Manufacturing Process of Ceramic PCBs

The manufacturing process of ceramic PCBs is advanced, relying on both material science and precision engineering. Here’s how leading ceramic PCB manufacturers make ceramic PCBs:

1. Substrate Preparation

- Start with ceramic material(e.g., Alumina powder), blended and calendared into thin sheets.

- Sheets are dried and cut to size, forming the base material or substrate.

2. Copper Cladding and Circuit Patterning

- Copper foil is bonded to the ceramic surface using direct copper bonding or electroplating (copper-clad ceramic).

- Advanced laser etching or photolithography forms the circuit layout.

3. Via Formation & Multilayer Stacking

- Vias (interlayer connections) are drilled using CNC or laser.

- Multiple ceramic layers of the PCB can be stacked and laminated for complex multilayer ceramic boards.

4. High-Temperature Firing (Sintering)

- The assembly is fired at high temperatures (800–1600°C), producing a hard, stable, insulating base with bonded conductors (the key process of ceramic).

5. Surface Finish & Final Assembly

- Optional coatings such as ENIG, OSP, or solder mask are added.

- Machines mount components using SMT or, for certain high-frequency applications, wire bonding or chip-on-board assembly.

6. Quality Control & Testing

- Every board passes through AOI (Automated Optical Inspection), X-ray for multilayer alignment, and electrical (E-test) for short/open circuits.

Properties of Ceramic PCBs: Why Use LHD TECH’S Ceramic Circuit Board?

The unique properties of ceramic PCBs stem from the inherent qualities of their ceramic substrate materials. These base materials are fundamentally different from the resin-based FR4 PCB substrates commonly found in standard circuit board technology. Let’s look closely at why engineers across industries increasingly use ceramic PCBs:

Thermal Properties

- Extremely high thermal conductivity: The core advantage of ceramic-based PCBs lies in their exceptional thermal conductivity. This characteristic makes them an ideal choice for efficient heat dissipation in high-power electronic devices and high-frequency circuit applications. Taking aluminum nitride (AlN) ceramic substrates as an example, their thermal conductivity coefficient can reach up to 180 W/mK. Such thermal conductivity far exceeds that of conventional FR4 substrate materials, and their heat dissipation performance is hundreds of times higher than that of ordinary FR4 materials.

- Superior thermal expansion coefficient: Most ceramic substrate materials exhibit a coefficient of thermal expansion that closely matches that of silicon chips and power semiconductor devices. This matching characteristic effectively prevents fatigue and cracking of solder joints caused by thermal cycling. In multilayer ceramic circuits and precision assembly processes, this property plays a critical role.

Electrical and Mechanical Properties

- Outstanding electrical insulation: Ceramic PCBs demonstrate distinct characteristics compared to metal-core substrates. They provide excellent insulation between circuit layers. This superior electrical isolation capability serves as a fundamental requirement for manufacturing high-end electronic devices. High-frequency PCB solutions equally rely on this critical insulating property.

- Hard, durable, and stable: The ceramic base material provides excellent mechanical strength and reliability.This makeceramic printed circuit boards highly resistant to vibration, shock, and thermal cycling.

- Corrosion and moisture resistance: Ceramic circuit boards are impervious to moisture, acids, solventsand most environmental contaminants, ensuring longevity even in industrial and harsh environments.

Advantages of Ceramic PCB Technology (vs FR4 PCB)

Choosing the right type of circuit board makes a major difference in electronics design. Here are some of the reasons engineers and innovators opt for ceramic PCB solutions over traditional FR4:

Advantages of Using a Ceramic PCB:

- Thermal management capabilities: Ceramic substrates are widely utilized in electronic circuits that demand high thermal conductivity. They are particularly suitable for applications such as LED lighting systems, power electronic modules, RF amplification devices, and high-frequency switching power supplies, all of which impose stringent requirements on thermal management.

- Compact and miniaturized design: Multilayer ceramic substrates enable the design of higher-density circuit layouts. This structural advantage eliminates the risk of thermal overload even under demanding operating conditions.

- Wide operating window: Ceramic PCBs possess the core capability to withstand extreme temperature environmentsand a capability that includes adapting to scenarios with drastic changes in high and low temperatures while maintaining stable performance, endowing them with stable application value in the aerospace, military equipment and automotive electronics sectors.

- Excellent support for high-frequency circuits: Ceramic substrates exhibit notably low dielectric loss characteristics and excellent long-term electrical stability. These performance attributes serve as a critical foundation for advanced RF circuit design. The manufacturing of microwave-frequency electronic devices likewise benefits from such highly stable substrate materials.

- High voltage and reliability: The unique dielectric strength of ceramic circuit boards enables them to withstand high voltage without breakdown. This characteristic delivers reliable performance and safety assurance for relevant applications. Typical examples of such high-voltage applications include power inverter modules and industrial control equipment.

Why Use Ceramic PCBs Instead of FR4?

- When your application needs excellent thermal performance and must survive in conditions that would destroy conventional printed circuit boards.

- In high-frequency PCB design, material properties directly determine signal integrity while also profoundly influencing overall system performance.

- For products where failure is not an option—think aerospace, medical, military, and automotive safety systems.

Applications of Ceramic Circuit Boards

Ceramic PCBs offer limitless solutions for demanding industries:

Power and High-Frequency Electronics

- Power modules for electric vehicles, wind/solar power inverters, and industrial motor drives.

- RF power amplifiers and high-frequency filters in telecom, radar, and aerospace.

- Solid-state relays and switching devices where thermal and electrical properties are paramount.

LED & Lighting

- High-power LED modules rely on excellent thermal conductivity to maximize brightness, longevity, and reliability.

- Backlight units for displays, LCDs, and automotive lighting.

Medical, Military & Aerospace

- Bio-ceramic PCBs in implantable medical devices, diagnostic sensors, and critical-care equipment.

- Aerospace applications including control modules, satellite communications, and signal routing in avionics.

- Military-grade ceramics in radar, secure communications, and guidance/control systems.

Renewable Energy & Industrial

- Solar panel assembly and PV inverters: Enhance power density and system reliability.

- Industrial controls: Where heat, dust, and vibration would kill a standard circuit board.

Design Tips: Getting the Most from Ceramic PCBs

Modern PCB design for ceramic substrates draws on unique capabilities:

- Leverage multilayer ceramic: We optimize compactness by stacking different layers of the PCB for signal and power routing.

- Explore hybrid assemblies: We use a ceramic PCB as a base for modules that include multiple chip types.

- Simulate thermal hotspots: Simulation analysis ensures that the highest-power component in a design remains within a safe temperature range. This analysis holds critical importance for applications that rely on high thermal conductivity materials.

- Match CTE meticulously: We select a ceramic PCB substrate with a CTE close to your silicon die and major components.

- Specify the surface finish: appropriate to your assembly method—ENIG for fine-pitch, OSP for cost, white solder mask for LED reflectance.

Choosing LHD TECH As Your Ceramic PCB Manufacturer

Means partnering with a reliable expert capable of fully unlocking the performance potential of ceramic substrates. We have established a professional trust system in the following areas:

- We specialize in a variety of substrate materials, including alumina (Al₂O₃), aluminum nitride (AlN), silicon carbide (SiC) and composite ceramics, and can provide precise selection recommendations based on your performance, cost and reliability requirements.

- We support advanced manufacturing process technologies such as DCB, LTCC and thick-film ceramics.

- Through comprehensive process controls, including electrophoretic testing, automated optical inspection (AOI), X-ray inspection and full environmental reliability testing. We ensure that every ceramic PCB meets stringent quality standards.

- With extensive experience in high thermal conductivity heat dissipation management, high-reliability electrical insulation and high-frequency/RF circuits. We focus on delivering solutions with superior thermal performance, electrical performance and high-frequency PCB capabilities.

- We are happy to share details of our past ceramic PCB solutions for similar applications and provide credible references through customer testimonials and case studies.

Conclusion: Is Ceramic PCB Right for Your Circuit?

If your circuit will be exposed to extreme heat, high frequencies, or must run flawlessly for years, ceramic PCBs offer unmatched performance. Their properties—excellent thermal conductivity, high dielectric strength, and robust chemical resistance—make them indispensable in advanced electronics, high-power, and high-frequency roles.

From the initial manufacturing process of ceramic PCBs to selecting the right ceramic substrate PCB for your application, each step can impact your project’s reliability, efficiency, and commercial success. While FR4 and traditional materials serve the majority of applications, only ceramic circuit boards deliver the elevated standards for the world’s most mission-critical electronic devices.