Introduction: Understanding PCB Components

Anyone who has ever turned on a smartphone or a computer will first see a densely packed Printed Circuit Board (PCB) covered with hundreds of thousands of electronic components. Resistors, capacitors, transistors, integrated circuits and electromechanical components are these independent yet closely coordinated electronic elements that together form a complete circuit which enables the normal operation of the device.

The key to understanding PCB technology lies in mastering component layout, component connection structure and component protection mechanism. Proper component arrangement and suitable PCB substrate material directly determine the performance, reliability and manufacturability of the circuit board. Whether people study the structure of ordinary circuit boards or design high-specification circuit boards for the aerospace field, the core principle of this work remains consistent: components are the foundation of circuit board design.

This technical guide delivers a comprehensive guide to circuit board components, with actionable knowledge and best design practices for enthusiasts, students, and professionals alike.

Comprehensive Guide to PCB Materials and Types

The core of each circuit board is not limited to those intricate electronic components; PCB material itself serves as the true cornerstone of every circuit board. The understanding and mastery of PCB substrate materials and their different types by technical personnel constitute a crucial and indispensable step in the entire process of circuit board design and manufacturing.

Overview of PCB Materials

A printed circuit board is typically manufactured using a lamination process. Its main structure is formed through the layered combination of the following fundamental materials.

- PCB Substrate Material:The foundation (usually FR-4 fiberglass, polyimide for flexible PCBs or ceramics for RF circuits). Each offers unique performance—polyimide, for example, handles high heat and movement in wearable technology.

- Copper Foil Layers:Essential for the flow of electrical current; thicker copper in multilayer PCBs accommodates high-current or heat-generating components.

- Dielectric Layers:Provide insulation and affect signal speed—critical in RF and high-speed digital designs.

- Solder Mask:The green (or sometimes blue, black, red) coating that prevents solder bridges and protects sensitive electronic components from contamination.

- Silkscreen:The ink layer displaying reference designators and polarity markings to help identify and place all the various components.

- Surface Finish:Treatments like HASL, ENIG or OSP protect copper pads and improve solderability during PCB assembly.

| PCB Material | Key Features | Common Use |

| FR-4 | Standard, robust, cost-effective | Consumer electronics, common PCB |

| Polyimide | Flexible, heat-resistant | Wearables, flexible PCB |

| Ceramic | Stable, ultra-low loss | RF circuits, radars, sensors |

| MCPCB | High thermal conductivity | High-brightness LEDs, power circuits |

| Rogers | Controlled dielectric, low loss | High-speed, RF, microwave boards |

Types of PCB

- Single-sided PCBs:Used in simple, low-cost electronics where only one copper layer and basic passive component usage suffice.

- Double-sided and Multilayer PCBs:Essential in more complex devices, allowing for component placement on both sides and advanced internal routing—a hallmark of today’s high-quality PCB industry.

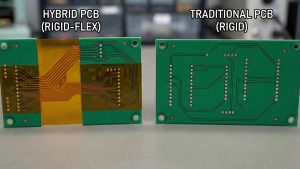

- Rigid, Flex, and Rigid-Flex Boards:Chosen based on mechanical requirements, flexibility and application scenario (e.g., foldable phones, aerospace).

- High-Frequency and RF PCBs:Special low-loss substrates and dedicated components control signal integrity.

PCB Component Categories: Passive, Active and Electromechanical Parts

Circuit boards feature a diverse mix of components. Each performing a unique role inside the electronic circuit.

Overview of Circuit Board Components

Passive Components

These board parts do not inject energy but are essential for controlling and stabilizing the flow of electrical current:

- Resistors(current limiting, voltage division)

- Capacitors(store and release electrical energy, filter noise)

- Inductors(store energy in a magnetic field, filter and smooth)

- Ferrite beads(EMI suppression)

Active Components

Rely on external power to function and actively manipulate signal flow:

- Diodes(allow current to flow in one direction; essential in power supplies and RF circuits)

- Transistors(amplify signal, switch currents in computers and power dimmers)

- Integrated Circuits (ICs)(miniaturized circuits such as microcontrollers and RAM—core to the function of the circuit)

- Voltage regulators(stabilize power for sensitive components)

Electromechanical Components

Electromechanical parts convert electrical signals into physical action or vice versa:

- Switches(open/close an electrical circuit, user interfaces or automated relays)

- Relays(isolate high-voltage circuits, often used for power control)

- Transformers(change voltage/current levels, permit safe coupling in power/communication systems)

- Connectors(provide a reliable electrical connection to external devices)

- Buzzers, crystals, and oscillators(sound, timing and clock functions)

Support Components

- Heatsinks(manage excess heat, protect heat-generating components)

- Mounting hardware(mechanical stability)

- Fuses(overcurrent protection, preventing short circuits)

Detailed Components List: Common Components Found on a PCB

A typical circuit board features a huge variety of components found across designs. Here’s a comprehensive list:

Common Passive Components

| Type | Common Use | Placement Notes |

| Resistors | Set currents, biasing, signal lines | Next to ICs, LEDs, power rails |

| Capacitors | Store and release electrical energy | Near power pins, signal filters |

| Inductors | Filtering, energy in a magnetic field | DC-DC converters, power stages |

| Ferrites | Blocking EMI on input/output lines | By connectors, power entry |

Key Active Components

| Type | Function | Key Placement/Notes |

| Diodes | Rectify, regulate, protect | Protect input, near relays |

| Transistors | Switch, amplify, logic | Signal or power circuits |

| Integrated Circuit | Perform complex functions | Center of functional blocks |

| Voltage Regulator | Used in power stabilizing | Input/output filtering nearby |

Vital Electromechanical Components

| Part | Application/Role | Example Use |

| Switches | User input, automation | Device on/off, mode selection |

| Connectors | Electrical connection | USB, headers, sockets |

| Relays | Switching high voltage/current | Power boards, industrial control |

| Transformers | Voltage conversion, isolation | Power supplies, communication |

Recognizing Components on a Circuit Board

The accurate identification of various components on a circuit board by technical personnel is a prerequisite for troubleshooting, equipment maintenance, and the forensic analysis of design schemes. Each PCB component is marked with a unique reference designator via the silkscreen layer on the surface of the circuit board. The marking methods for resistors (R1, R2), capacitors (C1, C2), diodes (D1), transistors (Q1) and integrated circuits (U1) all conform to the common conventions for such reference designators.

Polar components such as electrolytic capacitors, diodes and certain connectors have specific requirements for installation orientation in the PCB assembly process. Such polar components are usually marked with clearly distinguishable orientation marks on their surfaces. Operators must exercise extreme caution during the assembly operation to avoid damaging sensitive electronic components.

Component Placement, PCB Layout and Assembly Best Practices

Effective component layout formulated by designers is the core step of high-quality PCB design, and this step can directly optimize the signal integrity, thermal dissipation efficiency, testability and mechanical stability of the circuit board. Electronic devices are trending toward increasing miniaturization while circuit density continues to rise, making a rational component layout strategy an especially crucial element in PCB design work.

Key Best Practices

- Group components by function:Place parts that work together near each other (for instance, coupling capacitors close to IC power pins).

- Minimize critical path lengths:For speed-critical or analog-sensitive signals, keep traces short to prevent noise or signal degradation.

- Separate noisy and quiet circuits:Keep switching power supplies away from sensitive analog areas, using ground planes to shield and isolate.

- Allow for heat dissipation:Avoid clustering high-power or heat-generating components. Use thermal vias, copper pours and heatsinks as needed.

- Plan for test and repair:Ensure test points and frequently replaced components are accessible on the finished PCB board.

PCB Layout Strategies

- Use of Ground and Power Planes:Reduces voltage fluctuations, EMI, and ensures a solid return path for electrical current.

- Component Placement Designation:Modern CAD systems and technical guides allow pre-loading of preferred footprints for common components, streamlining design and assembly.

- Trace and Via Sizing:Calculate for current requirements and manufacturing tolerances, crucial for power boards to avoid overheating or excessive voltage drops.

Assembly Considerations

- SMT vs. Through-Hole Components:SMT enables automated high-speed assembly and compact designs, while through-hole is reserved for mechanical strength or legacy compatibility.

- Multi-layer PCB design:Increases routing options but raises manufacturing complexity. Essential for high-density, feature-rich electronic circuit boards.

- Soldering Process:Match solder paste, stencil design, and reflow profiles to the board’s material and component mix for reliable joints.

Types of PCB Design and Board Construction

The PCB industry offers multiple types of circuit boards for selection. Technical personnel need to familiarize themselves with the characteristics of these different board types. Understanding the specific impact each circuit board has on design decisions is an essential professional competency.

Single-Layer PCB vs. Multi-Layer PCB

- Single-Layer:Best for simple circuits, hobby projects, and some power supplies. Easy to produce but limited trace routing.

- Double-Layer Boards:Two copper layers allow for crossing traces and greater complexity without intricate via networks.

- Multi-Layer PCB:Often used in smartphones, computers, and advanced circuit board design; enables dense routing and power-plane distribution with greater EMI protection.

Rigid, Flexible, and Rigid-Flex PCBs

- Rigid:Standard for most consumer and industrial electronics.

- Flexible Boards:Used in wearables, aerospace, and automotive (areas exposed to movement or tight spaces).

- Rigid-Flex:Combine durability with form-factor adaptability; ideal for high-reliability devices.

Special Board Types

- RF and Microwave Circuits:Require special PCB materials (ceramics, PTFE) to ensure low signal loss.

- High-Speed Digital Boards:Prioritize controlled impedance and high layering for signal propagation.

- Power Boards:Use thick copper, wide and short traces, and polarized, large-value capacitors to deal with current surges.

Technical Guide Table—Selecting the Right Board Type

| PCB Type | Key Features | Best Use |

| Single-Layer | Simple, low-cost, quick turnaround | Prototyping, toys |

| Multi-Layer | Dense routing, power/ground planes | Mobile, servers |

| Flexible | Bendable, fit into complex housings | Wearable, automotive |

| Rigid-Flex | Space-saving, hybrid structure | Aerospace, medical tech |

| RF/Microwave | Low loss, stable at high frequency | 5G base stations |

PCB Manufacturing: From Component Selection to Board Assembly

The design and manufacturing of circuit boards is a systematic process involving multiple stages, which covers several core steps including PCB component selection, layout planning, material procurement, and assembly.

Component Selection Strategy

- Formulate a Components List:Start with generic parts of a circuit—resistors, capacitors, inductors, diodes—then specify unique or custom electromechanical components (switches, relays).

- Selecting PCB Components:Purchasing personnel shall prioritize the selection of market-verified reliable suppliers and verify the lifecycle and compliance status of various components. Designers must ensure the proper derating application of critical or heat-prone components, and select components whose voltage withstand, current withstand, and temperature withstand thresholds are significantly higher than the actual maximum expected values of the circuit.

- Plan for Obsolescence:Always have alternatives in your components list for long-term products.

Board Fabrication and Assembly

- PCB Fabrication:Multilayer boards are produced using lamination, imaging, etching, drilling, and plating. Materials chosen must be compatible with component types and assembly methods.

- Component Sourcing and Inspection:Ensure authenticity, regulatory compliance (like RoHS), and batch traceability for high-reliability applications.

- Assembly Stages:SMT and/or through-hole components are placed, soldered (using reflow and/or wave processes), then inspected visually and electrically.

- Quality Assurance:Use automated optical inspection, X-ray for BGAs and in-circuit/functional testing to catch soldering errors or misplaced components.

Protecting Sensitive Components: Thermal, Mechanical, and Electrical Considerations

Thermal Management

- Heat Sinks and Thermal Pads:Essential for power MOSFETs, regulators, and other heat-generating components found in power conversion or LED driver PCBs.

- Copper Pours/Vias:Used under ICs (especially QFNs, BGAs), drawing heat away from the package.

- Thermal Simulation:Predicts hotspots and helps guide component placement in early PCB design stages.

Mechanical Protection

- Standoffs/Housings:Keep delicate board parts safe from vibration or impact.

- Potting/Conformal Coating:Shield entire PCB assemblies from moisture, dust, and voltage arcing—frequently used in automotive and outdoor products.

Electrical Protection

- EMI/RFI Shielding:Prevents interference between sensitive components like RF ICs and switching regulators.

- Transient Suppression:TVS diodes, MOVs, or specialized ICs clamp surges and protect against ESD.

- Fused Power Rails:Prevent permanent damage from short circuit events.

Troubleshooting, Testing and Maintaining Circuit Board Components

Testing Techniques

- Visual Inspection:Check polarity, solder bridges, and misaligned board parts before power-up.

- In-Circuit Testing (ICT):Automated tester checks every net and component—crucial in quality-focused PCB industry production.

- Functional Testing:Runs the design in a real-world scenario to verify end-to-end operation.

- Boundary Scan (JTAG):A must for complex digital boards, providing insight into IC interconnections without physical access.

- Thermal Testing:Ensures components maintain safe operating temperatures, vital for long device lifespans.

Common PCB Issues and Fixes

| Problem | Likely Cause | Solution |

| Dead board | Open circuit, failed fuse, reversed diode | Inspect traces and replace blown/failed components |

| Intermittent faults | Poor soldering, component aging | Touch up joints, swap out suspected board parts |

| Noise/EMI issues | Ground loops, inductor/capacitor selection | Reroute traces, improve decoupling, shield sensitive components |

| Overheating | Component overload, poor airflow | Improve derating, move heat sinks, increase ventilation |

Maintenance

- Regular Cleaning:Prevents corrosion and leakage between tightly spaced components in humid or dusty conditions.

- Predictive Replacement:For critical applications, replace time-sensitive passive components (electrolytic capacitors, relays) before end-of-life.

- Field Repairs:Use sockets for parts likely to fail or require upgrade, which simplifies maintenance and minimizes downtime.

Key Trends Shaping PCB Component and Circuit Board Design

1.Miniaturization and high-density design have emerged as key trends in the current electronics industry. The continuous consumer demand for smaller-sized and more intelligent devices has directly driven the growth in demand for high-density circuit boards. Today, circuit board components are widely assembled using surface mount technology (SMT). Advanced integrated circuits and passive components generally adopt miniature package specifications such as the 0201 and 01005 sizes. Designers must rigorously verify the recommended layout pad designs for fine-pitch components and confirm that their PCB assembly partners have the corresponding process capabilities to accurately mount and reliably rework such miniature circuit components.

2.Multilayer PCBs and advanced substrate materials are gaining widespread adoption. Modern smartphones and wearable devices commonly utilize printed circuit boards with eight or more layers. These precisely engineered stacked structures effectively isolate noise. They also provide stable power distribution networks for the devices. High-speed electrical signals thereby gain reliable transmission pathways. Best Practice: Apply careful stack-up planning, with attention to PCB material selection (e.g., FR-4, polyimide, Rogers) to optimize for electrical performance and manufacturability.

3.Increased Use of Electromechanical Components Touchscreens, MEMS sensors, tactile feedback motors, and programmable relays are now common electromechanical parts enhancing user interaction and system intelligence.

4.Industry Push Toward Environmental Sustainability RoHS, REACH, and conflict materials regulations are just the start. The next generation of PCB components will focus on recyclability, biodegradable substrates, and reduced hazardous waste. Tip: Only specify components with verified compliance and documented eco-friendly certifications.

5.Integration of High-Frequency and RF Circuits From WiFi and Bluetooth modules to 5G and IoT, more circuit boards must handle high-speed signals. Component choices, PCB layout, and materials must support signal integrity and effective impedance matching.

6.Data-Driven and Automated Designs Modern PCB design leverages simulation, AI-optimized trace routing, and real-time BOM management tools. This reduces errors, accelerates time-to-market, and optimizes material usage.

Best Practices for Robust and Reliable PCB Boards

- Design for Manufacturability (DFM):Consult with your fabricator and EMS provider early in the process to align board stack-up, track widths, and assembly constraints.

- Use a Bill of Materials (BOM) Tool:Digital BOM tracking streamlines component sourcing, lifecycle management, and ensures regulatory compliance for all circuit board components.

- Simulate Before You Build:Tools like SPICE, thermal, and signal integrity simulators help avoid costly iterations and improve circuit reliability—especially for boards with sensitive or high-speed signals.

- Protect Sensitive Components:Always include ESD protection, especially for boards with connectors exposed to the outside world.

- Prioritize Accessibility:Clearly label test points, connectors, and ensure components that may need to be replaced (such as fuses or relays) are physically accessible.

- Stay Proactive About Obsolescence:Maintain second-source suppliers for critical components used in your boards, and subscribe to end-of-life notifications from original manufacturers.

Technical Guide: Essential Steps for Selecting PCB Components

- Understand the Function:Know how each component in your electronic circuit contributes to the overall board operation.

- Consider the Application’s Environment:Are there requirements for thermal stability, vibration resistance, or humidity tolerance?

- Verify Electrical Ratings:Always match or exceed operational voltages, currents, and frequency ranges.

- Check Availability and Lifecycle:Avoid rare or soon-to-be-discontinued board parts unless absolutely necessary.

- Document and Review:Keep schematic symbols, footprints, and datasheets well organized for all the common components and specialized parts of your circuit board.

FAQs: Questions About PCB Components, Materials, and Circuits

Q1: What is an overview of PCB and its most important parts?

A: A PCB (printed circuit board) is an engineered platform for mounting and electrically connecting electronic components using conductive traces on substrate material. Key parts include passive resistors and capacitors, transistors and integrated circuits (ICs), switches, connectors, and specialized electromechanical components.

Q2: Which components are essential for every PCB board?

A: Common passive components (resistors, capacitors, inductors), active components (transistors, ICs), and electromechanical parts (connectors, switches, relays) are essential for most electronic circuits.

Q3: What steps are involved in the design and manufacturing process of a circuit board?

A: Steps include schematic design, PCB layout (ensuring best component placement), gerber generation, board fabrication, component sourcing, PCB assembly, testing, and final system integration.

Q4: How do I protect sensitive components from electrical damage?

A: Use ESD protection, follow layout guidelines for high-speed or noise-sensitive components, thermal simulations for heat-generating components, and select robust PCB substrate materials for the environment.

Q5: Can I mix through-hole and SMT components in the same PCB design?

A: Absolutely! Many complex boards combine both technologies—known as hybrid assembly—to maximize strength for connectors or relays, while keeping the rest of the board compact with SMD.

Q6: What causes a short circuit on a PCB, and how can I prevent it?

A: Shorts can arise from solder bridges, misaligned or misplaced components, or foreign material. Prevent by using appropriate solder mask coverage, precise placement, and post-solder cleaning processes.

Conclusion: Mastering the World of PCB Component Selection

Navigating the world of PCB design requires more than just understanding individual components; it demands an integrated approach to selecting, placing, and protecting all the components of a circuit. Whether you’re examining the simplest board parts or engineering a multi-layer solution packed with advanced electromechanical components, every decision—PCB substrate material, layout, assembly process—directly affects reliability, performance, and manufacturability.

This comprehensive guide was crafted to help you form a deep understanding of circuit board components and the best practices for assembling, sourcing, and maintaining your own high-quality PCB designs. Remember that choosing the right PCB component, planning for obsolescence, and applying rigorous testing are key to success in the ever-evolving PCB industry.